how much PSI were you running for that dyno Hypsy??

6 PSI this weekend with one pull to 10PSI. i was running it at 12PSI for a bit but it started bucking and felt like it was running out of fuel right there so i wanted to retune.

when i dyno'd right after having the kit installed the car made 222HP and 224lb/ft w/ a 12.6 a/f ratio on 7 PSI.

this time it made 177HP and 200lb/ft @ 4300RPM and a 13.0 a/f. at 4400RPM the car just shot right down to 10:1 then back to 14.4:1 and stayed there. that was the only time in 7 runs that we could get it lower that 14.1:1

I used to race cars, now I race myself.

5K PB: 24:50

10K PB: 54:26

I wonder if its just the Ecotec ecu adjusting back to 14.7:1, like a lot of ecos this is happening to?

yeah i have that problem what Mcnulty is saying ^^^

i took out my gm/sc injectors and replaced them with for red tops 30lbs and gonna check tomarrow to see what the wideband says.....if it go's to back to 14.7 again then im gonna have to think about EIS ...or maybe a SAFC can correct it....

well im gonna try the walbro plus a SAFC. i can get the walbro cheap (maybe free) from a buddy to test out. also stealing his SAFC to try. but after a lot of testing the only thing we can conclude is that the eco ECU is adjusting back to 14.7. Even though we had enough fuel in there for a 10:1 ratio (as noticed when the car suddenly kicked into open loop.)

another thing i forgot to mention is our TB sucks. if you hook it up to a scanner you'll see it only opens...get this...to 87%. EIGHTY SEVEN PERCENT! NO GOOD! i ground down the stop and now it opens to 98% which is good enough for the ECU to interpret as 100% open. Took a lot of metal off in doing in though. So make sure you have a scanner right there with you as you grind it down.

I used to race cars, now I race myself.

5K PB: 24:50

10K PB: 54:26

well keep us posted..or at least me..im in the same boat as you =( you'll prob have your safc + pump setup befor me anyways...

Maybe if the TB is not opening all the way the ecu may not go to open loop-and if it dosent then it will continue to adj for 14.7 no matter what.

good point....if thats logical =/

actually i went today and tested on the wideband with the ford Red-tops....

Click me!

whats your idle pressure and FMU disk? i took off the Nology ignition system and im gonna try again. if that doesnt do it im gonna try the SAFC alone since thats free. if that doesnt do it then ill do the walbro

I used to race cars, now I race myself.

5K PB: 24:50

10K PB: 54:26

my idle pressure is at 32-35 PSI..my FPR can go as low as 25. it idles pretty damn good at that tho. i dont use disc's...i have the cartech adjustable FMU..turn the knob =) but its pretty much maxed out..

Checked my TPS its like 87.3% BUT MY THROTTLE BLADE IS WIDE OPEN??????

SHIFTED-- If you read this what do you think?

its not wide open

look closely and you'll see it has a slightly angle to it. grind down the stop to 100% and you'll see wide open. mines at 98% which is good for 100% to the computer and it still wont kick out of closed loop. oh well.

I used to race cars, now I race myself.

5K PB: 24:50

10K PB: 54:26

how about we stay on the topic here. This post isn't about eco af ratios. Its about how to install teh walbro and if someone has ?'s on that . Thanks.

<img src="http://img.photobucket.com/albums/v292/dragmyz24/shoppedcav2.jpg">

Rush Racing

http://www.gettherush.com/

I also installed mine without cutting the cup. However, my car isn't running, although I'm doubtful it's pump related. Just FYI it is possible.

Matt S.

<a href="http://www.cardomain.com/id/kindofcavy"><img src="http://img61.exs.cx/img61/8537/J-Sig8b.jpg" alt="Image Hosted by ImageShack.us" /> </a>

Built not bought, check that!

alex16cav wrote:ok well this weekend i finally decided to install my walbro fuel pump.

Pump number: GSS340M

From: http://www.autoperformanceengineering.com/

When you order it ,tell them that you are putting it on a cavalier. and to send a installing kit, which costs $15 (give or take).

you need the o ring, a new accordion looking tube, or you can use the stock one if you don't mess it up.

the wire connector.

clamps

and the filter. (white sock)

To drop the fuel tank, you just need some disconnect tools for the fuel lines. Re-leave the fuel pressure before u do them, it makes it easier and less messy.

Once you have the tank out, and the fuel module out. the "cup" looks like this.....

You need to modify the cup so that the pump gets fuel.

For all the people who had trouble under a 1/4 a tank of gas. this is what you do.

You can see how much i cut. basically the whole bottom. You do know need the plastic tube that is inside the module, or the little yellow thing.

Make sure to have the accordion tubes on all the way. and clamp them down.

Also, you can see how the connector was plug and plug, no cutting or anything required.

Make sure you have the fuel pump all the way down. You use the stock rubber cup thing that the stock fuel pump was in. its hard to get down into the hole, so lube it up some. and it will go down.

Also the tube was hard to get on, did the same thing. I also made a small slit on either end of the tube, to get them to stretch over the nipple type things. Only do that if you cant get it on, otherwise you might cut too much, and have to get a new tube.

I think that is all there was to it. Put the fuel tank back in, and disconnect the lines.

When i started the car i had less then 1/4 a tank of gas and it started perfect. I primed the pump three times just to makes sure. And i bypassed my msd inline.

I drove it around, the car feels so much better. My egts are 200 degrees lower, and my car doesn't have a hesitating feel, like it did with the msd inline.

Huge thanks to Nick, Changeforabutton. He basically walked me through a ton of it. Especially the cutting and what not.

considering the pics didn't work for me. I fixed them

____________________________________

Primer Counts as Custom Paint Right?

BTW: This is my Sig.

I'd like to explain the 1/4 tank fuel cut issue's based on some testing i did.

First, I installed the walbro pump into the fuel bucket as it was in stock form with no cutting. The bottom of the fuel bucket has two valves to let fuel in. One is a venturi powered intake valve, and the black line that everyone mentions cannot be used anymore... that black line is supposed to power this venturi. The venturi will use some of the pump pressure to help draw in more fuel to fill the fuel bucket higher than the level of the tank. Since this line cannot be used anymore, you loose the ability of the venturi valve.

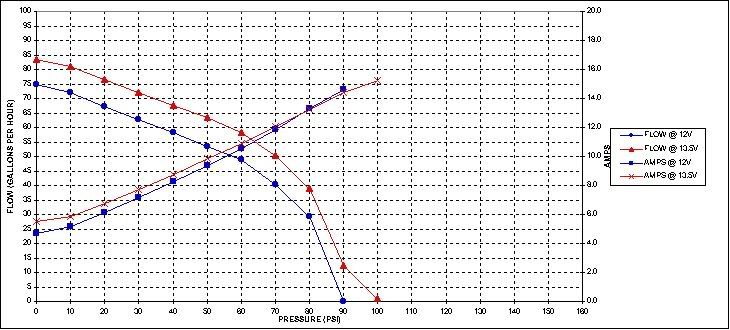

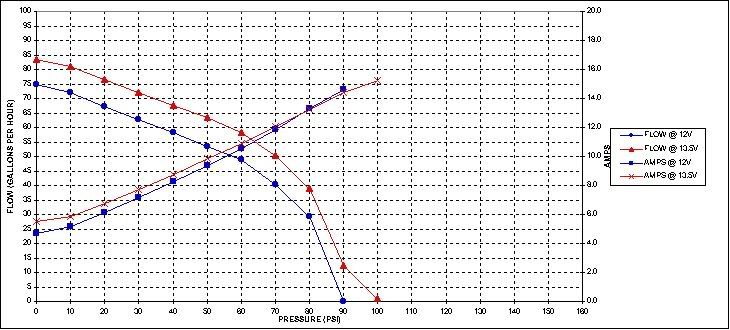

next, the other valve is just a basic check valve. If the tank level is higher than this check valves level, then fuel is allowed to flow into the fuel bucket. I have found that when i installed the walbro 255 into the bucket WITHOUT cutting it, this check valve would only allow enough fuel into the bucket to support 40 gallons per minute. The walbo is trying to pull in enough fuel to supply its advertized 70 gallons per minute, so guess what happens? the fuel bucket is pumped dry, and the pump begins pulling air, and pumping it into the lines.

To solve this problem you MUST cut the bottom of the fuel bucket off. This will allow the walbro pump to pull directly from the fuel tank, rather than just the fuel bucket. So, in doing this, you render that restrictive check valve out of the equasion, and the pump can pull all it needs. you get full 70 gallons per hour flow, and no air. great.

the side effect is that since your venturi valve is no longer functional, the fuel bucket is not pumped up higher than the fuel tanks level like a stock setup would do. This is the reason all of our cars must have over a quarter tank of fuel. the pump sets higher in the tank than floor level, and when you hit the gas and G's throw all the fuel to the back of the tank, the pump can again pick up air. To solve that issue, the only thing you can do is keep more than a quarter tank of fuel in your car at all times.

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

typo- i cant edit my post, but when refering to pump flows, i said "gallons per minute"... this should have been "gallons per hour"

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

notice how detrimental voltage is to the pumps flow ratings? Keep in mind that the pump will be pulling ALOT more current than your stock pump. Sending more current thru the crappy 20guage wire is going to create a heated wire, and ALOT of voltage drop over the course of 15 feet. While your at it, you should upgrade your pump power and ground wire. Think abou it.... 14.4Volts X 12Amps = 174 WATTS. You wouldnt power a 200 watt amp off of 20guage wire would you? so why would you risk your entire engines fuel system on that? Upgrage to 12 guage wire, and a dedicated 30A relay. Before doing the re-wire, i found i was only getting 10.3 volts to the pump thru the crappy stock wire. Now i get 13.7v. WAY better.

You can get the stuff you need cheap, such as....

and wire it up using a regular relay you can get for a couple bucks down at the parts store....

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance