Honestly I want to figure out WHY it's there before I decide how to vent it. I was gonna give it vaccum from the turbo intake... after I run it through the catch can. Unsure right now.... I need to figure out how it works and why it's there.

I haven't ruled out any options yet.

-Chris-

-Sweetness-

-Turbocharged-

Slowly but surely may some day win this race...

chris i have noticed that the car will burn some oil off, not a huge amount, i dont have any leaks. i have been wondering about the pcv lately tho, i go to honda-tech alot and all the hondas run 2 to 4 lines off their valve covers but our cars dont have a valve cover, so would it help to vent the cam towers threw a catch can. and im also curious as to what does the rubber hose coming off the timing chain cover do, does it vent crank case pressure?

R.I.P. Brian Klocke, you will never be forgotten

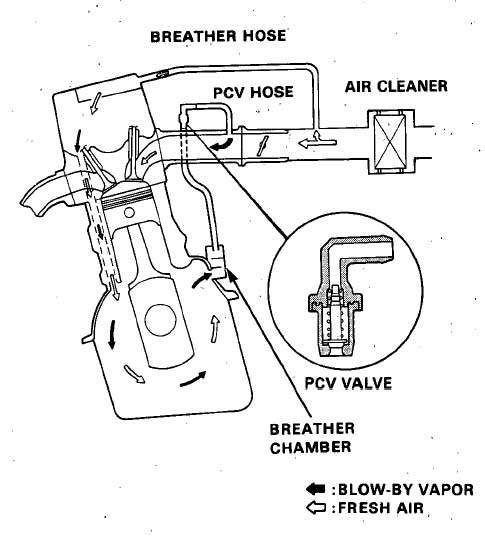

I decided the other day to investigate how the ecotec PCV system works, and after comparing notes with Chris we discovered the two systems are very similar.

so here's the ecotec PCV system in pictures. I think you'll find the 2.4 system almost identical.

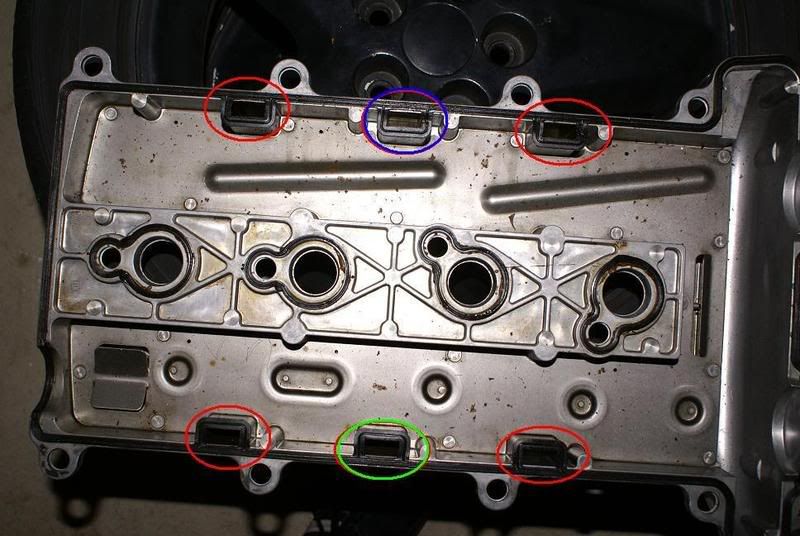

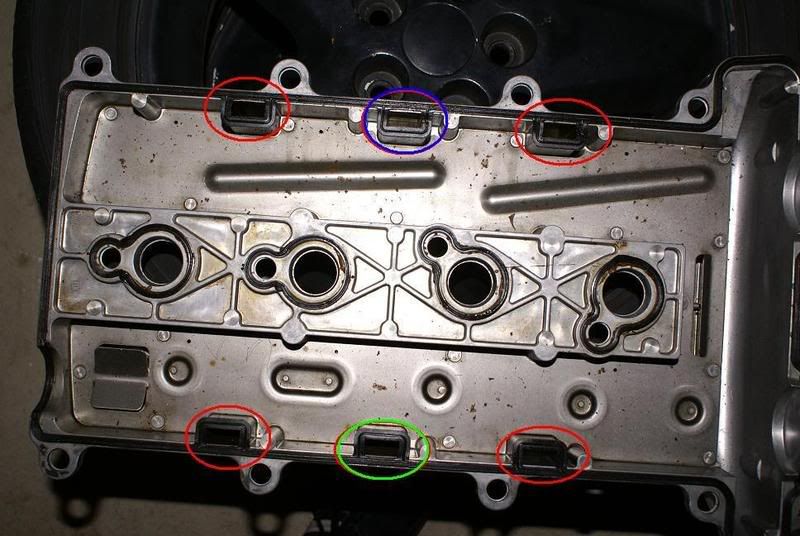

underside of the cam cover. Mating ports are colored similar all throughout the pictures. If its the same color, its connected together (although its all ONE system as a whole, I'm showing where individual pieces mate together)

the L61 head (2.2)

the infamous "small port between #2 and #3"

the green hole connects to the intake manifold via this hole

for comparison, here's the LSJ head (2.0)

the port is still there, just in a slightly different location

valve covers for both engines always have 6 portholes (weird since the L61 doesn't have a mate for the underside of the blue porthole.

the mating surface of the block

directly below is the bores for the balance shafts, and further below that is the crank and rods

for a real world test, I pulled the hose from the nipple of the cam cover and checked it for vacuum.. its def got that going INTO the valve cover. this is the IN of the PCV system.

Another thing i thought i would mention, as is done alot on the imports, but i have yet to hear mention of here is using the exhaust to create a venturi vacuum.

instead of using the pre-turbo intake for vacuum, and sucking hot oily blow-by air back into the intake.... they run all PCV "vacuum" to a line that goes into the exhaust... if the line is plumbed into the exhaust at a steep angle, the venturi effect of the presurized air blowing past the angled port, creates a suction, much like an airbrush or suction feed sand blaster.

This way you still have your vacuum... but you are not sucking oil or hot partly burnt air back into your intake to dillute your cold fresh air charge, and crapify your intake system.

What the hell was GM thinking when they designed these systems??? If only we knew who the engineers were, we could ask them ourselves haha.

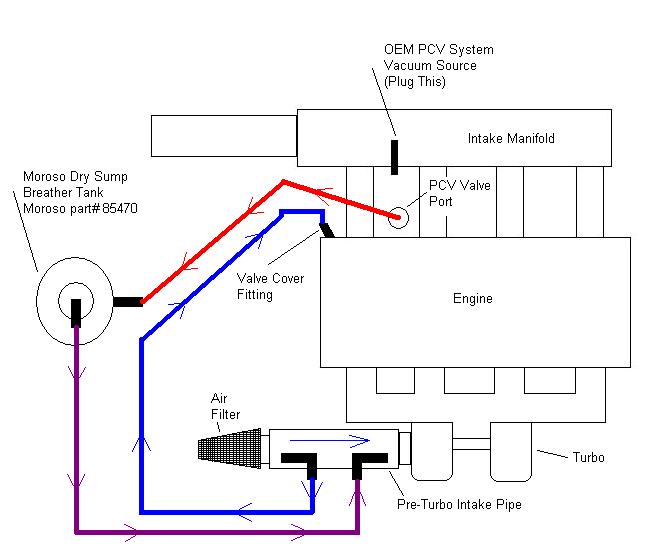

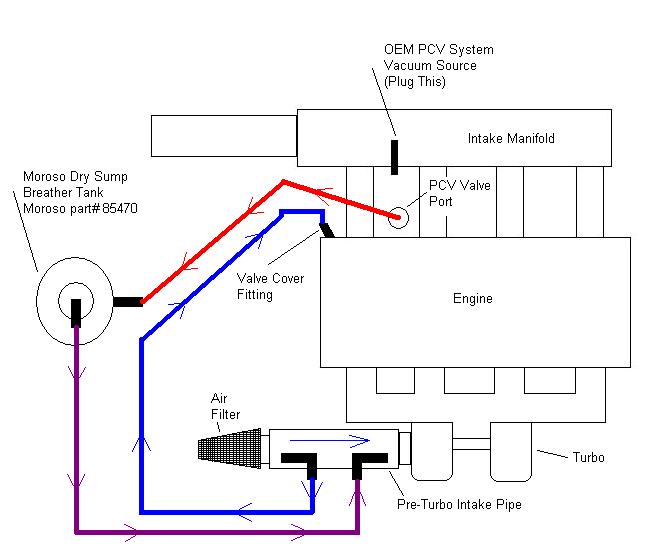

SweetnessGT wrote:With that said, I'm thinking about running my pcv system like this: (picture borrowed from site above)

-Chris-

Chris, I have always wondered if our system actually doesn't run a true PCV and rather just positive pressure vent instead, no recirculating. That would actually exsplain everything as far as the plumbing goes.

Also, keep in mind that between your "suction" and "vent" lines in the pre turbo air tract wont have much pressure differential to create a good recirculation. You'd be better off leaving your fresh air intake line straight from the atmosphere to increase differential. I can actually tell you exactly the pressure differential if you can get me exact IDs of the hoses and intake piping and mass air flow rates of your engine at different RPMs. I really wouldn't mind doing it to find out, both with the suction hose in the intake and suction from the atmosphere...anyway....

Also, if your talking about like a 1-3 psi differential or so, which I think would be realistic in a turbo intake you also have to take into account how much pressure blow-by in the cylinders is going to create as that will negatively effect your pressure differential.

I really honestly believe these engines do not offer fresh air recirculation and rather just evacuate the positive pressure in the crank case.....would exsplain damn near everything. The only other thing I can think of is maybe the whole stock system runs entirely start to finish under vacuum with the port in the head being the exhaust and the hose in the intake being to suction although under vacuum at times but not as high a vacuum as the intake runner.....but then we'd see that one runner having bad build up and non of the other runners wet which is obviously not the case....the whole intake system gets full of crap........obviously pointing to the intake hose out of the plastic separator as being the exhaust.

Does that little port in the head get full of crap? - leading towards it being an exhaust also?.....if so I really think this system is really just a positive crank case pressure blow-off system and that's it.

I really think Ken is on to something as I've also heard of people just saying screw it and run a line to the exhaust side, although ruining passing emissions testing.

<table>hello</table>

I'm not sure if that hole gets gunked up. I know it's connected to all FOUR runners thru the intake manifold flange. This explains why every time I pull off a stock intake manifold on an LD9 all 4 head ports have like 1/8" of crusted on oil crap on the bottom of them which I need to scrape and clean off.

I see what you mean about the pressure differential... I could definitely do that... except that it's illegal here in canada to do that. if it's seen visually it's a $220 ticket. I need to plumb it back in somehow. DItto the exhaust slash cut idea - I need to pass emissions here so I'm screwed.

Basically it's a circulating system from what I can see. Vaccum is pulled through the vent tube in the stock expansion box, it travels down through the air oil separator, then up to the timing chain housing. It goes into the chain housing, circulates through there and the crank case, and is sucked UP through the block up into the port in the head. It is then spread through all 4 runners and put through the combustion chamber and evacuated out the exhaust.

We've been blocking the MOST important port on the system, forcing it to somehow go backwards - which it can't. I have basically had no PCV... and on a boosted motor that's just about one of the stupidest things I could do.

Other than the intake pipe to the turbo I have nowhere else to place the inlet and outlet. I'd hate to get pulled over and my hood lifted and handed a $220 ticket for a breather BUT this system NEEDS to work properly, or I"ll be rebuilding another turbo in 4000 miles.

-Chris-

-Sweetness-

-Turbocharged-

Slowly but surely may some day win this race...

I have a stock LD9 WITH the PCV in working order(or rather stock order) and the timing chain housing is DEFINETLY pushing air, NOT sucking air. Also, the PCV port is actually only connected to one runner, not all four, once you put the gasket in the manifold it can't get across to all the runners. IT still doesn't add up man!!!!

All the runners get coated and only one gets access to that port, which means the hose running to the intake tract is the vent, not the fresh source.

I've resorted to just blowing holes in other peoples ideas rather than bringing new ideas to the table........I know, I'm an a$$hole.

<table>hello</table>

^^^ It's a very confusing PCV system, far from traditional. Much like the ecotec one except the ecotec runs the one side off the valve cover.

I too have experienced my crank case "vent tube" *pushing* air while idling... ditto coming out of the oli dipstick and the oil fill cap. But it's not a constant push, it pulsates with the motor. Also I've always wondered if the air "push" I'm feeling is just the chain spinning around - if you notice GM has in a way baffled the vent in the crank case so that oil doesn't just splash into it.

Looking at any traditional PCV system the PCV valve is under vaccum at all times from the manifold, the vent is run to the intake side for a pressure differential. Looking at our system, we have that set in place. I DO believe that oil is still in the air going to the intake which is why GM used an air/oil separator on the way, but some still gets through all the way to the intake and enters through the throttlebody.

I'm really at a small loss as to what to think but going with traditional wisdom and comparing it to countless stock PCV setups, I'm led to believe that the path of flow starts at the air intake tube and ends in the manifold, going into whichever runner the hole is routed to.

I'm hoping some more people can bring some thoughts to the table.

And Joshua - it's ok that you blow holes in my theories. I'm not here to preach misinformation... I want to find the answer once and for all. What's most important to me is that I get the PCV hooked up properly and functioning so my motor can finally breathe properly.

-Chris-

-Sweetness-

-Turbocharged-

Slowly but surely may some day win this race...

I thought back to my supercharger install on my ECO (which also has that port)

I recall having to cut the LSJ gasket to work with the L61 to allow that port to vent ( the port is higher on the manifold, like inline with the top studs to mount it to the head)

If you look at a blown LSJ intake manifold you will see that that port is routed in the manifold to a point before the impeller blades.. (vacuum source perhaps)

If you look closely you can tell in this pic

I will admit I am guilty of running just a breather of the valve cover, I was planning on eventually routing it to a catch can and my intake tube but I have not been in a hurry to change it because I have not noticed ANY oil exiting from this location since (and I am using a white paper filter)

I know its not the same motor, but assuming GM does what they do so well, it is possible that that port serves the same purpose on both engines...

It would be nice to figure out which side is the intake, and which is essentially the exit though before you go and route anything...

I would think it would be safe to say that that port should not be blocked off though...

** FOR SALE**

http://www.j-body.org/forums/read.php?f=24&i=110879&t=110879

ok, just an interesting tidbit of info.... dont know if this helps anyone in any way.... but the LD9 MP45 kit from GMPP.... it gives you a little nipple that comes out of the bottom of the SC manifold... and connects via hard line to a pre-blower nipple just upstream of the TB.... (normally would be vacuum at all times) so this make sense...

but i just removed the hardline, and ran a rubber vac line in its place so i could reoute it to a new vacuum source...

well i slapped my vacuum pump up to that line, and sucked it... seeing what it did... and it did NOTHING!!! within like 2 pumps it was at max vacuum... it was almost as if i had the other end plugged, and just sucked the air out of the line...

i thought maybe there was a check valve, and it didnt suck, and only blew... so i hooked up the hose to the outlet of my lil handi-vac pump thingy... and pumped a bit of pressure in there... after a few pumps it poped the line right off.

So GM went thru the trouble of installing that lovely nipple just to screw it into nothing? or is something wrong with my engine where that port is clogged or blocked?

mind you the GMPP MP45 uses o-rings, there is no intake gasket, so it cant be a gasket blocking it...

This doesnt really bring anything new to the table here... but just found it very odd... as important as this lil port seems to be, there are alot of things that seem to be blocking it....

To find out which is Enter and exit, would it not be as simple as being the same as the direction the crank rotates?

Looking back at the diagram Chris posted about the LN2.

Imagine it's the LD9 and you're looking at it from the timing chain housing angle. Assuming the crank is rotating counterclockwise from this POV, the Vaccum "should" be the nipple closest to the left of the block (The rear if your looking at it from the front of the engine bay) and the Vent should be the closest to the intake manifold (unlucky for us, it's built into the flange on the head for the intake manifold lol)

This post was more so directed to ExESIVEFIRE..

Quote:

It would be nice to figure out which side is the intake, and which is essentially the exit though before you go and route anything...

SweetnessGT wrote:

I too have experienced my crank case "vent tube" *pushing* air while idling

sad story.. fired up the car after workin on it and i say crap its starting to rain i better hurry up... rub my fingers together and realize its not water... ingeniously i decide to bend down to search the engine bay finding oil vapors spraying in my face

it was dark... n00b move of me :/

on another note

gm did build the supercharger kit for the motor. follow suit and realize what they did for our system and use that givin info to find out how our PCV system works. obviously they did what they did for a reason so use that to feed the research as well as tell you where to hook that head port to.

The pvs system on the 2.4 works like so. The hole in the head you can blow in or out. Has no check valve. The one that goes to the intake has a slight blow out can hardly tell if using the 2.4 manifold. If using the 2.3 manifold and not making the hole smaller (like the 2.4 gasket hole) in the vaccum hose you have to run, by a restricto,hard line that goes to the interior vaccum of the the car is the right size or a smaller vaccum line. You will be able to feel a good amount of vaccum. More than what it is suppose to be so anyone with the 2.3 manifold should keep that in mind.

Also i'm not sure about the hose on the cam housing but i can check to see if it blows out still with the pvc stuff hooked up. It did before i knew about the pvc and the 2.3 manifold. On another note when i blew in or sucked on the vaccum port hose that goes to the head air would come out of the intake hose and suck in a little.

If you think about it though everybody that is boosted seems to be having a little problem with the pvc stuff. On most vehicles with pvs that are boosted there has to be a backflow prevention valve hooked up. On our engine the port in the head won't see vaccum when smashed open or when there is no vaccum. So that port isn't doing anything at the time if not boosted. If boosted it's going to blow air into the hole in turn probably blowing oil out the hose that would go to the intake.

Be bet would be using a 2.3 manifold and drill the hole for the head in it. Drill and tap it or take a vaccum hose connecter like i did for now to see if it fixed my burning oil problem. Start with it a little big and turn it in a piwcw of sand paper till it fits tight in the hole. Add silicone around the hole since the 2.3 gasket doesn't go down that far. Run a vaccum line to the middle port on the manifold or the one by the throttle body with a back flow prevention valve.

Also the 2.4 gasket does get vaccum from all the ports who ever said that is wrong. If it didn't the pvc wouldn't work for a spit secound or have enough vaccum. Sorry for grammer as too i worked last night and have yet to go to bed.

I had a stock manifold in my hand the other day, and when I shot some brake cleaner through the port, it would flow out of the ports of 2 and 3. It's entirely possible it is in fact connected to all 4 ports, but I didn't have compressed air handy to experiment further.

My thinking is: we're all aware there's a lot of positive pressure in the timing housing. You can feel it both through the open oil fill hole, as well as if you take that hose off. That hose is connected to the right side (left when facing car) of the air-oil separator. Perhaps there are passages cast into the block where this positive pressure circulates, collecting vapours and whatnot, and returning to the left side of the separator, where it then feeds up to the intake tract. The hole in the head is to collect vapours from the upper end of the engine, drawn out by the intake charge passing through the runners. That's my guess...whether it makes any sense is up for plenty of debate

14.330 @ 96.37mph

Thrice . wrote:To find out which is Enter and exit, would it not be as simple as being the same as the direction the crank rotates?

Looking back at the diagram Chris posted about the LN2.

Imagine it's the LD9 and you're looking at it from the timing chain housing angle. Assuming the crank is rotating counterclockwise from this POV, the Vaccum "should" be the nipple closest to the left of the block (The rear if your looking at it from the front of the engine bay) and the Vent should be the closest to the intake manifold (unlucky for us, it's built into the flange on the head for the intake manifold lol)

No, the direction of flow has nothing to do with the direction of crankshaft rotation. The crank generates windage but not circulation in any organized fashion, there's just no way. The PCV circulation is only generated by a pressure differential across two points of interest....ie: intake and exhaust of the PCV system, no other means.

Blown Phoniex wrote:Also i'm not sure about the hose on the cam housing but i can check to see if it blows out still with the pvc stuff hooked up.

It does.

Blown Phoniex wrote:On most vehicles with pvs that are boosted there has to be a backflow prevention valve hooked up.

Our engines have one, its in the crankcase below the block seperator and looks to slow or block flow OUT or rather up into the separator from the crankcase.

BlownBlackZ wrote:I had a stock manifold in my hand the other day, and when I shot some brake cleaner through the port, it would flow out of the ports of 2 and 3. It's entirely possible it is in fact connected to all 4 ports, but I didn't have compressed air handy to experiment further.

Interesting, realy didn't look possible but never did check for myself.....hmm...could I be spreading miss information...perhaps...thats what I get for not checking myself.

<table>hello</table>

Um i'm not talking about the oil separator. Also there is nothing there to keep boost from blowing in. i had it off and looked at it unless i missed something. all i seen was where the oil that is blown out of the timing cover goes down. Then there is the hole in the block and a type of baffle that is suppose to keep the oil from going into the hose that would go to the intake.

i'm talking about the hole in the head needs a back flow prevention valve. A pvc system won't work clear right with out vacuum. Yea it will let pressure out but not clear like it should. People using the 2.3 manifold like my self that doesn't tap the manifold for the whole in the head and hook it to vacuum. Will burn oil like crazy in 3000 miles i ended up burning 2 quarts to 2 1/2 all together and i'm n/a. I hooked the hole in the head up to a vacuum port on the ho manifold and what you know i burnt less than half a quart(keep in mind my 2.4 swap consists of a 2000 2.4 with 140,000 dog piss miles and all is original cept water pump is starting to weep).

If you were boosted i could see real bad problems if using the stock 2.4 manifold. Since that hole when in boost will get boost so there is only one way for the boost and pressure out of the cam cover straight out the line that would originally go on the intake box. You would be better off blockin the hole so it won't see boost at all. But you will still leak boost around the rings but shouldn't be close to the say 9lb's of boost building and going through the hole. Better deal would be cut a a spot so you can tap the head hole and screw in a fitting and seal off the lil slots in the manifold some how and run a vacuum hose with a back flow prevention valve. Also think about it the eco and ld9 pvc is some what the same if using a stock manifold. Well you will loosing boost through the pvc also.

Best bet for use ld9's is using the ho mani like most are and hooking the pvc up like stated by taping a hole in the manifold and sealing around the hole. Then vacuum line and back flow prevention valve. With a filter or catch can on the intake tube hose.

For eco's i believe it is the lsj manifold or the 2.4 eco manifold that has a different hole on it then a stock eco head. And do the same with the 2,3 mani so you won't have to seal off the ports. I know nothing about the eco so i might be wrong on that part but you should get what i mean.

Blown Phoniex wrote:Um i'm not talking about the oil separator. Also there is nothing there to keep boost from blowing in. i had it off and looked at it unless i missed something. all i seen was where the oil that is blown out of the timing cover goes down. Then there is the hole in the block and a type of baffle that is suppose to keep the oil from going into the hose that would go to the intake.

Yeah, you missed it. I'm not talking about the oil seperator, I'm taking about the aluminum plate thingy that you can only see from the bottom side of the crankcase. It doesn't look like a check valve...maybe its just there to help keep crap loads of oil in the windage from getting into the seperator. IDK.

I agree with your thoughts on the hole in the head to see vacuum and all that. idk, I really think a whole new setup would be in order for the people who are boosted since your trusting a backflow valve to keep your oil pan in one piece.

What if you connected the seperator line to a catch tank and put an air pump to push air throught the small hole in the head?!?! You would have fresh air in and a vent....the vent would be large enough to support blow-by....what do you guys think? Yes this would effectively run the system backwards but does it really matter? - no check valves in place......

<table>hello</table>

Why not look at the turbo cobalts setup and go from there?

Funny thing is today I was messing with my PCV hose. I had it connected to a small breather filter and it would emit oil vapors out so I could smell oil just a bit.

I already drilled a hole in my intake manifold to match up with the head.

Now stupid thing is I removed the breather and connected the PCV hose to a "T" fitting that then went to a hose to the t-body and the other side of the "T" fitting to the brake booster. Now I started the car and it ran with high RPM's without me even pushing on the gas, plus it smoked out the muffler like crazy.

Now I replaced everything back to normal and it'll start but hesitate and turn off. Could this of @!#$ up my PCV or do i just need to clean up the intake manifold, intake head ports, and spark plugs cause they might be full of oil?

Well I later learned the PCV hose needs to connect before the tbody which means on the intake pipe and not the tbody or manifold.

Sorry to thread jack but since this thread is on subject I just needed some help.

GMR has got nothing on this

O i've never been inside of a 2.4 yet so you are possibly a little right but not really. The hole in the head you can hook a hose right up to it and blow and suck on it just fine. No check valve. Because on a na motor its not needed. Look at the gm kit why did they put the hose before the rotors and not in the manifold similar to a stock 2.4 manifold. Because that hole isn't suppose to see boost its the only thing i'm saying. A check valve though depending on which way it is installed will let you suck in air but not blow air through. Which would block boost from pressurizing the crank case. In turn blowing oil out the hose that orignially went to the stock intake box thing.

The only problem is the only way to install a check valve would be with a 2.3 manifold, but could be done on a 2.4 manifold with a little bit of modifing. I bet you if you tapped the whole in the manifold for the hole in the head. Hooked a vaccum line to it to a vaccum port on the manifold with a check valve installed in the middle to where it only draws vaccum not seeing boost. Installed a filter on the end of hose that ran to stock intake or what ever to prefer. Just as long as it vents to the air. You will get rid of most if not all of your blow by. Or the oil blowing out.

Keep in mind i'm not boosted yet just trying to get time to mock up and make a bracket for my old p600b procharger. I will be. Although my 95 ta i built the motor myself after cracking almost every ring. Got a little boost happy. Any way it would blow oil oil out the valve cover breather before the build and figured it was mainly cuz of the rings. Well after sinking $6,000 in to the motor (391,cammed,p&p head and such). Uprgrading to a d1sc at 14 lb's. After broke in and dyno tuned it still blew oil after getting into boost. Come to find out who installed the first kit had the pvc system seeing boost after several calls to ati. Got it fixed and been fine since. The 2.4 pvc system is similar to the lt1's.

Blown Phoniex wrote:O i've never been inside of a 2.4 yet so you are possibly a little right but not really. The hole in the head you can hook a hose right up to it and blow and suck on it just fine. No check valve. Because on a na motor its not needed. Look at the gm kit why did they put the hose before the rotors and not in the manifold similar to a stock 2.4 manifold. Because that hole isn't suppose to see boost its the only thing i'm saying. A check valve though depending on which way it is installed will let you suck in air but not blow air through. Which would block boost from pressurizing the crank case. In turn blowing oil out the hose that orignially went to the stock intake box thing.

Idk exactly where your going with this one....please re-read my post, I mentioned pushing air through the hole in the head, NOT putting vacuum to it.

Blown Phoniex wrote:The only problem is the only way to install a check valve would be with a 2.3 manifold, but could be done on a 2.4 manifold with a little bit of modifing. I bet you if you tapped the whole in the manifold for the hole in the head. Hooked a vaccum line to it to a vaccum port on the manifold with a check valve installed in the middle to where it only draws vaccum not seeing boost. Installed a filter on the end of hose that ran to stock intake or what ever to prefer. Just as long as it vents to the air. You will get rid of most if not all of your blow by. Or the oil blowing out.

Exactly what is the point in running the PCV while not in Boost? I'd imagine most of everybody's problems are happening while in boost, but then running the line to a vacuum port and a backflow prevention will make your system effective only while part throttle. If you would just have the head port open straight to the atmosphere or even throw a vacuum pump on it then it would be effective 100% of the time....I really dont think a vacuum source and backflow prevention will be a good idea while boosted...doesn't really solve the problem.

<table>hello</table>

heres a better pic of how i tapped the oil seporator intead of the head flange

R.I.P. Brian Klocke, you will never be forgotten