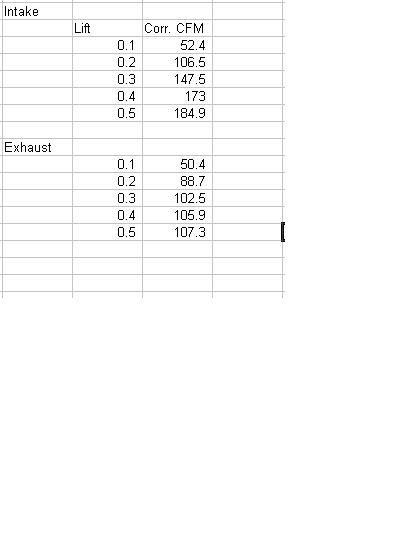

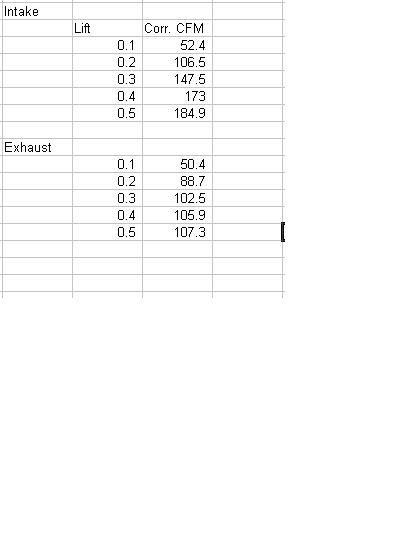

Well I just got my head back from being flow tested, for the "before" numbers

here are the numbers

now that i got the test done. i'm ready to start the port and polish on it.

Does anyone have any good helpful suggestions before I start? anything i should know so i don't eff something up?

This is for a 2200 btw.

well no one replied so i'll let you guys know how it turns out once i get it done and flow tested again

Don't try to match the exhaust ports to the header, use a stock 2200 exhaust gasket as a guid for port matching. Make sure the port on the head is slightly smaller than the gasket or header, about .025" on all sides will be good.

Reduce the valve guide in the runners to as close as reasonably possible to the runner's roof.

Match the bowl (the area just above the valve seat) to the valve seat. Be careful not to touch the valve seat with any cutters, stones or sanders.

Most of this is already covered in the

SA Motorsports DIY Guide, but a couple of points I wanted noted.

MadJack wrote:Don't try to match the exhaust ports to the header, use a stock 2200 exhaust gasket as a guid for port matching. Make sure the port on the head is slightly smaller than the gasket or header, about .025" on all sides will be good.

i was planning on using the stock gasket, and i was also wondering about the lip on the exhaust...but you answered my question already

..thanks to you and OHV notec (who posted in the other thread) for the helpful tips