Ok what should I do exactly for the port and polish. Need to know so I can tell the shop the right things. Im gunna be N/A for a while till I can save for a total rebuild of a differant engine. On that note I want to get roller rockers what ones shoul I get. I also want the 1mm valves. Do I need anything else.

I am also looking into getting a cam but where do I go to and what should I tell them to regrind? Plus where do I get a stock cam to send in if they don't have them?

Im not a motor guy yet so help would be nice

Oh yeah my current mods are up to date in my profile. but here they are if your to lazy to look

If there is anything that I missed let me know thanks

Engine:

* Warm Air Intake

* Rk Sport Motor Mounts

* Cavalier Connection pulley kit

* 2.3 HO Throttle body swap

* Magna Flow High flow cat

* Custom 2 1/4 pipe

* Magna Flow performance muffler

* Pace Setter Header

* B&M Shift Plus

Disclaimer:

Dey see me Trollin' Dey hatin' for trollin dey trying to catch me ridin dirty.

If some one hasn't answered by the time I get off work this afternoon, I'll get you some info and links for you. In the meantime, try searching, I sure you've seen some of the larger threads concerning those questions.

get a dremel and a bottle of jack and have fun

but if i knew i would help you but i dont know......

Head porting:

Don't open up the intake runners at all, just remove the casting flaws. Open up the exhaust runners a bit, they're undersized. Smooth out the transition to the valve seat, knife-edge the area around the valve guide, deshroud the valve faces, polish the exhaust runners and combustion chambers, smooth the area where the plug protrudes, and smooth out the short-side radius. This should be about all you can do without getting into reshaping, which means $$$$ unless you're TIG proficient. Oh yeah, don't forget to have the valve seats widened for the oversized valves, I'd suggest a 3-angle cut for a street car.

Rockers:

Obviously Jack's roller rocker thread is the place to go to for this, but let me remind you of the 2200 valve springs thread, where I posted max lift specs for your engine. If you're going to go with a more aggressive cam, you don't want high ratio rockers, as you'll surpass the limits of the rest of your valvetrain (which sadly to say, doesn't really have a fix without some fairly major machining). Personally, I like the stock 2200 rockers (enough that I wouldn't spend $$$ to replace them). Before we could recommend a cam, we need to know exactly what your goals are for the engine. Will it see boost? What kind of powerband are you looking for? What are your tuning options? Having flow specs for the head after porting would also help out A LOT. Also, if you 'build' a new motor down the road, will you use the same cam? What are the goals for that motor? I also have to make sure you realize the block should come out to replace the cam (I said SHOULD to all you corner-cutters), and if you're going to do that, you might as well replace the pistons/rods, then you should also do bearings, oil pump, timing set, gaskets, milling,..........where do you decide to stop? I'd suggest leaving the stock cam if you're planning another motor down the road, or just do it right the first time and be thorough.

fortune cookie say:

better a delay than a disaster.

My goal is possibly nitrous and mostly the fastest that I can get n/a without nitrous. I would like to run a decent shot to so I will prob be doing internals since I'm gunna be in there with the cam. Now this is a daily drive but I don't really care if I have lopey cam I just want it to be fun to drive ya know. The suspension in there and if fun as hell just need to make it get into and outta the corners faster esp for auto crossing

. I would like to start drag racing so hope that helps with what power ranges your asking for.. I just really need the specs on everything I need to just order parts and go to the shop and tell them what I need done. I know I am asking a lot and should figure it out on my own. But as I stated I am not a motor guy and don't really know where to begin when it comes to working the numbers. I just know the names of some of the parts that I might need

Thanks for all the help. Oh yeah I am almost outta posts so if anyone wants to ask me some more questions I am on aim almost all the time so hit me up there or email me thanks.

Disclaimer:

Dey see me Trollin' Dey hatin' for trollin dey trying to catch me ridin dirty.

*disclaimer* this is just MY opinion

From cam to crank:

Clevite77 cam bearings

Crane HR-232-328 cam regrind (hp peak ~6000rpm, tq peak ~4500rpm)

LT1 lifter conversion (refer to OHV lifter thread for specifics, I may have some extras pretty soon here)

Crane custom length 5/16 thick-walled pushrods (the last thing you will purchase)

stock rockers (require no adjustment for a good install, give .505" lift with reground cam, already low-friction)

SI stainless +1mm valves

new stock locks and retainers

Comp Cams 26915 LS1 springs (105# @1.800")

SPRING SEATS MACHINED .100" (guides would have to be machined the same amount. This gives clearance for the lift, as well as room for the springs, which will sit about 130#) ***make sure to have the seats sonic tested for sufficient meat, there may be a coolant jacket nearby*** The longer 94-97 valves could be used for less machining depth, but you will need two different length pushrods, and you'd have to use aftermarket rockers, meaning more or less lift depending on the ratio...I'd stick with 2200 valves

valve seats opened up 1mm and all other headwork previously noted

cometic NA headgasket

ARP head studs

forged pistons 11:1, pins, rings, appropriate bore & hone

Eagle rods, clevite77 rod bearings

cross-drilled and micropolished journals

clevite77 main bearings

balance rotating assembly

ARP main studs

New stock timing set (or you could

try fitting the double-roller chain and gears with the stock tensioner...not recommended unless you know what to look for, but it hasn't been proven

not to work)

Melling M98 oil pump

crank-scrapers.com scraper&windage tray setup (great for the autoX)

150 shot, direct port injected

(progressive controller would obviously be of benefit)

I'd estimate 150whp NA based on the dyno2200 simulation

Of course, all this is assuming a good sized project budget (set aside ~$5k if someone else is doing everything for you)

Also, remember, this puts you in street modified for solo2, you'll never place again

I'm sure Jack or slow will chime in with corrections or additions

fortune cookie say:

better a delay than a disaster.

I figured someone would chime in for me while I was at work!

Thanks, Josh.

Josh, That is definitely a radical build!!! He would definitely need HP Tuners to get the rev-limiter moved up to about 7000-7400 rpm and the shift points moved up also, to just before the limiter kicks in. A custom made intake would help also, with atleast a 56mm TB, a 58-59mm TB might be more appropriate. A change of gears would be in order, I believe the 4sp(in the LS) has about a 3.90:1 ratio available though typically not geared that low), along with atleast a 3000 rpm stall TC. This set-up might be good, if he had a Getrag 5 speed, but I think it might be a little too much for the 4T40E. a built TH125C/3T40 would be able to handle it, but he would need the 3.33:1 final drive, the underdrive chan and gears (37/33 tooth gears) and smaller diameter tires, something in the 22.5-23.5" diameter range to get him to an equivalent of a 3.90+ gearing.

All this is considering the cam intake centerline and lobe separation angles are the same as stock(in. CL109* ATDC, 114* LSA). Just about all the cam manufacterers don't reccomend changing the cam phasing too much, only about +/- 1*with the mild to moderate lift cams. Reducing the base circle too much can cause the lobe to slip on the core tube(the cam uses lobe pressed/swedged onto a tube, instead of a solid shaft, still durable and safe for moderate lift cams though). Another thing to consider is, the power range of our motors will be about 400-500 rpm higher then an equivalent SBC grind(the 2.2/2200s use the same lobe design as the SBC, so you can use the lobe profiles from a SBC hydraulic roller cam), so if your going with the power ranges of a cam from the manufacterer, remember to add the additional rpms to the power range.

Matt, if you want to stick with a cam that will work with what you have now, look into the Crane HR-204-214 ground on the stock CLs. The stock CLs will give you a good idle and wook well with boost or nitrous. That cam will give you 204* duration @ .050"intake and 214* on the exhaust and (theoretical) lift of .458"(in) and .482"(exh) with the stock rockers. This is just .002" over the limit of the stock springs, which is a gamble. The stock rocker arms were measured to actually give you a 1.54:1 ratio, which would keep you in a safe range, if you willing to take a gamble. If you use a set of 1.5:1 aftermarket rockers, you would have .429"/.452" lift, which the stock springs will handle with no problem. With your current set-up, a P&Ped head with the +1mm valves, the head surfaced about .020" and the 1.5 rockers and a 2.3L TB, your looking at upto 30lbs/ft of torque across the entire rpm range and upto an adittional 33hp, according to Desktop Dyno(if all things are done correctly and tuned w/ HPT. Note: your results will vary). Remeber torque is what makes the car move, while HP is how fast it will go, the more torque, the quicker it'll accelerate!

Enough Rambling! Good Luck, let us know what you decide.

Yeah, it was more on the "wild" side of things, but he said he wanted NA power

Also, on a side note, Crane called. Apparently my stock cam spec'd at 113* LSA, so either their equipment isn't as accurate as they say it is, or the OEM lobe-presser-onner is a little flakey (that must have been why my car felt so torqey lol).

And since we're on the engine building subject, I picked up my short block (minus cam) today. I doubt you remember, but I had expressed concern earlier about my new pistons being significantly "taller" (longer distance from wrist pin centerline to top edge) than stock. Well, when I rotated the motor I noticed the piston protrudes almost .040" from the deck (deck was also surfaced, but only 5 thou or so). I measured the stock headgasket thickness to be about .065" with plenty of room to clear the overbore. Now, I know you're supposed to leave clearence for things like bearing wear and rod stretch (forged steel rods though), am I cutting it too close with .025-.030"?

And, apparently they didn't create the extra mounting boss for the '82 tensioner, he said there was already a boss, and the tensioner could be mounted with the correct bolt. Now, I double-checked, and there's nothing (one is kind of close, but still an inch or so off) so I'm taking it back next weekend.

But, he said one of his employees is really into building our little LN2s, and he can get '82 guides and tensioners from his supplier. I don't buy it, but I'm going back in a week to have them check out the valve spring seats on a head as well as bore out my '82 cam gear, so I'll find out for sure.

And a note to everyone looking to have a motor built, race shops cost $$$, do your own assembly lol (my wallet was crying), and find a decent rebuilder to do any bore/honing (so it's only like half the price).

Good news for ARP main stud users...there's still plenty of extra stud for mounting the crank scrapers, and using the bolt stretch measurements they found correct torque to be 65 ft-lbs using ARP moly lube (will be 75-80 with motor oil)

fortune cookie say:

better a delay than a disaster.

Crane did the measurements on my cam and they said it was 114* LSA. Kinda hard to figure who's readings are more accurate, Crane or Crane? Or is it GMs manufacturing? BTW, the lobes are ground after they are pressed on.

As for the head gasket, don't forget to subtract fo the gasket compression. The specs for the compressed thickness for a stock gasket is .055", which would cut another .010" form the thickness. Also, don't forget to measure you valve-to-piston clearance, before you try to start the motor.

Do you have the 6th Edition of the Chevy Power Guide? It states that you drill and tap the tensioner bolt hole for a 8X1.25 bolt, then epoxy a spacer (.350" long, .700" O.D., .343" I.D.) to the block and spotface the spacer to the same hight as the existing tensioner bosses and the front bearing bulkhead(approximately .266" above the front cover mounting surface), to make-up for the boss.

Hmm, if they're cut after being pressed on, you've got to wonder...

The gasket I measured was used off of the engine when I took it apart, so it had already been deformed, but I forgot about the elasticity of the steel (even after two college courses dedicated to it lol). So, now I'm down to 0.015-0.020

What do you think?

I had measured the valve heads at .501" lift, and they obviously weren't going to work with the 2.2L head (protrude .330" below the head). I was planning on swapping to the 2200 head since I was ditching the 2.2L head I had built anyway, but with this new piston info, that may not work either (2200 goes about .145" below, or .125" with stock rockers). So, I guess the options are flycutting the piston faces or milling down the raised edges...I never should have listened to Chris Kelchner and gotten these pistons...looks like I have to pick up a syringe and graduated cylinder tomorrow to see how much piston I can lose

Although, thinking about it some more, flycutting probably isn't feasable due to te canted valves being lowest by the cylinder wall and leaving too little material in that area, I dunno

Would you happen to know the stock piston to deck distance?

(This motor is kicking my butt)

fortune cookie say:

better a delay than a disaster.

.015-.020" is way too close! Any float what-so-ever and/or the thremal expansion would close that up in no time.

The valve protrusion, was that with the 1.84" intake valves? If so, that may change the plans with my next head. My other option is getting a set of 1.811"(+2mm) intake valves made. I may have to go with that, with a set of 1.497"(+1mm) exhausts. Either way, I need custom made valves to clear the rocker arms self-alighning tips.

Surfaceing the pistons is an option, if the piston deck is thick enough. Check with a reputable machine shop about surface milling the pistons and posibly flycutting the valve reliefs, I thich they should be able to do it, but they would know better. I have seen a few pistons that have been cut faily close to the outer edgeof the piston, but that was a BBC.

I didn't write it down, but if memory serves me correctly, the stock piston-to-deck clearance was .026"

Protrusion was measured with stock valves, so add on another .01" for every 1mm added to the valves (assuming valve face sits at 30-degree angle to deck face, the maximum possible by eyeballing it...actually more like 15-degrees)

That stock piston depth can't be right, at stock lift the valve protrudes .225" on the pre-98s, so it must be more like .260".

However, from what I posted in the old thread, my new pistons were approximately 1/16" (not a very precise measurement) taller than the OEM units, meaning the stock depth would be more like what you said.

Hmmm, maybe I'm not measuring correctly...or I'm missing something. I may have to go out to the yard again to pull a head and see what the piston depth is

DOES ANYONE HAVE A SPARE BLOCK!?!?!?!? lol

fortune cookie say:

better a delay than a disaster.

Alright, shoot me now. I was thinking about it for a minute, and obviously the valves are never anywhere near full lift when the pistons are at TDC. Heck, mine aren't even at .050" yet with the new cam...

Now I just want to figure out what my new compression ratio is

fortune cookie say:

better a delay than a disaster.

OHV notec wrote:

DOES ANYONE HAVE A SPARE BLOCK!?!?!?!? lol

I might have one after tonight! Something's broke and I've lost a lot of power. I'm hoping it's not a spun bearing or something like that. Maybe a bad lifter. I could live with a bad lifter. Much easier fix. Whatever happened it's making some god awful noises and it's running like the poo. I picked up another motor at the junk yard just in case.

If ya want to save alittle doe ray me on port and polish and try it out google standard abrasives they sell grinding/sanding stones but also give you a step by step play on 1 stage 2stage and 3 stage porting 3angle <> 5 angle jobs turbo. supercharger. nos. where to grind etc

http://img86.imageshack.us/img86/4235/jim25ek.jpg

here it is

Standard Abrasives porting guide is definately a must read for the DIY guys/gals

fortune cookie say:

better a delay than a disaster.

OHV notec wrote: Well, when I rotated the motor I noticed the piston protrudes almost *edit .035" *edit from the deck (deck was also surfaced, but only 5 thou or so). I measured the stock headgasket thickness to be about *edit .055" *edit with plenty of room to clear the overbore. Now, I know you're supposed to leave clearence for things like bearing wear and rod stretch (forged steel rods though), am I cutting it too close with .025-.030"?)

In regards to this question, I read this today:

"So how closely can the pistons approach the head face? Although it comes under the heading of "don't do this at home" I have run the static piston/head clearance down to

as little as .024-inch in a 350 with stock rods and close-fitting hypereutectic pistons. The pistons just kissed the head at about 7,000 rpm. As far as power is concerned, an associate of mine ran some tests in a nominally 450-horse 350 and found that each 10 thousandths of quench reduction was worth approximately 7hp. If you are building from scratch, make maximizing the quench your number one priority toward achieving compression and avoiding detonation."

linky

input?

Does anyone know the compressed thickness of the SCE copper gasket?

Also, what kind of gearing would a 236* .050" duration cam require do you think?

fortune cookie say:

better a delay than a disaster.

That is a good read, Josh! Very informative. I know most, but there is some new thing I learned from that.

I didn't find any info concerning an SCE Copper HG, but

FlatOut Gaskets has them listed for our motors. They are available in 13 thicknesses from .020"-.125" and any bore size you want. See their link to their catalog for part number information.

A cam with 236* duration @ .050"?!?! What are you building, a race motor?

Using the Crane catalog as a reference, you will need a cruse rpm @ 60 mph of 4200-5000 rpm. Using there formula for determining your cruse rpm, you would need about a 5.38 gear with 24.9" (stock diameter) tires. You looking at a power band in the area of 3500-7000 rpm.

You must be planning on really ringing the rpms out of that motor!

Make 'er SCREAM!

I found my copper gasket, .062", wouldn't help as much as I hoped.

Race motor? kinda... I have these messed up pistons and I'm trying to find something to do with them (about 15:1 right now). I've been throwing around some numbers and messing with some different combos. I figured I could get them down to 13:1 with some good headwork and keep a low quench, but I'm not sure how low I can go

Then I was messing with some different cam combos to try and get big power and knock down the dynamic compression ratio at the same time. I was looking at the SR-236/350 grind in particular because it would be the biggest I'd feel safe using given the retainer to seal clearance, and it makes more power than the smaller ones lol. 5.38 gear though? Don't see that happening anytime soon, although the motor wouldn't be too difficult to do given what I have now. I dunno, I'm just throwing things out there right now, definately open to suggestions.

fortune cookie say:

better a delay than a disaster.

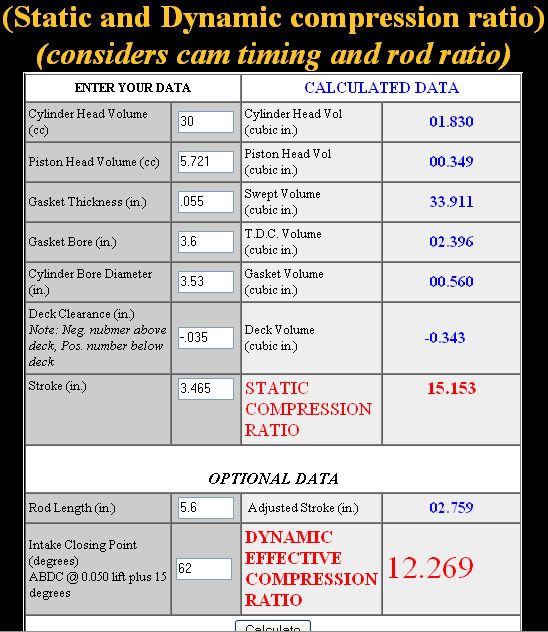

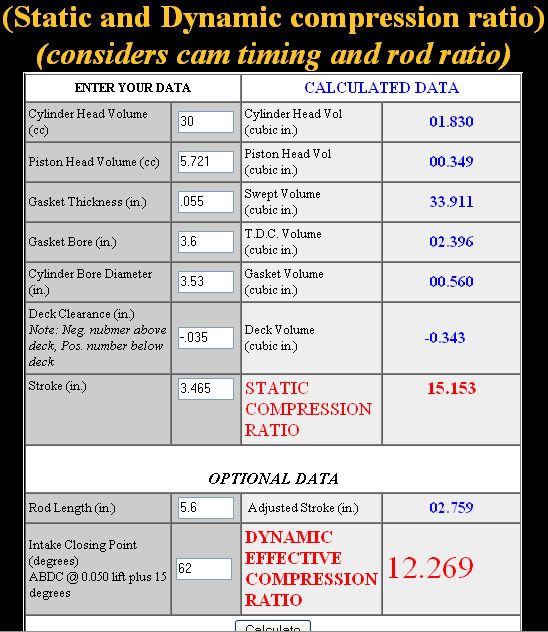

Well, I decided to make my own dynamic compression ratio calculator using some basic diagrams and geometry, fun stuff.

Looks like my formula is pretty close to whatever is "accepted", but my measuring skills are lacking since I'm getting a stock static ratio of 9.8:1

I know someone will be wondering, "if you can just use the online calculator, why waste the time?"...Simple, I have Manufacturing Processes homework due tomorrow morning so I had to use my procrastinating time for something

fortune cookie say:

better a delay than a disaster.

I see one thing wrong, your rod length. I don't know if the calculator is rounding the length, or if you got it from a source that was wrong, but stock is 5.589" and the Eagle rods are 5.890". It may only be .010"-.011", but that can be a significant amount dealing with CR.

Could I see the numbers you used on the stock calculations? I'll compare it with the numbers that I have.

Something to add as for reducing the CR, try using one of the thicker FlatOut RCC gaskets. If you get the right one, you can still get the .030"-.040" piston to head clearance and reduce the CR at the same time. The lock-wire chamber sealing ring will help control the sealing of the head to the block also. This should help you with being able to use a milder cam that you could find a resonable gear for. It's not like were using a F@&d 9", with unlimited number of gear ratios!

MadJack wrote:I see one thing wrong, your rod length. I don't know if the calculator is rounding the length, or if you got it from a source that was wrong, but stock is 5.589" and the Eagle rods are 5.890". It may only be .010"-.011", but that can be a significant amount dealing with CR.

Could I see the numbers you used on the stock calculations? I'll compare it with the numbers that I have.

Something to add as for reducing the CR, try using one of the thicker FlatOut RCC gaskets. If you get the right one, you can still get the .030"-.040" piston to head clearance and reduce the CR at the same time. The lock-wire chamber sealing ring will help control the sealing of the head to the block also. This should help you with being able to use a milder cam that you could find a resonable gear for. It's not like were using a F@&d 9", with unlimited number of gear ratios!

Yeah, I knew my rod length was off a little. I was looking for the stock length and couldn't find it, so I took a quick approximation on the Eagle rods since it's practically impossible to measure directly. I had no idea I was off by so much though, WOW. Luckily it only affects the DCR by a few hundreths of a point. Question now though, why are the Eagle rods SO much longer than stock? That alone will raise the compression a couple points...

Here are the stock measurements (w/ corrected rod length):

chamber vol___gasket width___gasket thickness___piston depth__bowl vol___bore____stroke___

30.000cc_____3.600"________0.055"____________.026"_______19cc______89mm___88mm__

This gave a static ratio of 9.785. Add in the 5.589" rod length and an intake closing 53* ABDC I get a DCR of 8.477 (low-grade gasoline maximum, obviously not right)

The two numbers that are most likely to be wrong are the combustion chamber volume (my tools weren't incredibly accurate), or the piston depth (still haven't been able to verify this number). Although I probably should measure the bowl volume directly, as it is hard to do geometrically.

I'm definately considering a thicker gasket (and those RCCs are awesome). To get a good quench I would need a thickness of about .070". Using a modified chamber volume of 37cc (which gives a stock 8.89:1 SCR) the gasket would drop the static and dynamic CR about 3/4 a point each, down to 12.4 and 10.0, respectively (DCR stilll on race cam). This is MUCH better, but I still need to drop another point to point and a half to be reliable on 91 octane (yeah, crappy west coast gasoline grades)... and even more for a streetable cam (although the motor definately won't be daily-driven, so streetable refers to anything close to the 3.73 (I think) max gearing).

fortune cookie say:

better a delay than a disaster.

Can you get ahold of a CC'ing kit (a graduated burret and piece of plexiglass/lexan with a fill hole)? If so you can cc the head and piston dish, or even better, cc the the piston in the bore, using the 1/2" down fill meathod.

As for gearing, 3.73 is max for the TH125C, but with a 23.5" diameter tire, you would get approximately a 3.95 equivalent. Still not quite where you want to be, but getting closer.

Crane does have a milder Street Roller Cam, the

SR-228/338-2S-12 IG. This grind on the billet core will give you a powerband of 2900-6500 rpm, a little more reasonable (about 500rpm lower). With this acm the cruse rpm drop to about 3400-3800. The tire and gear combo listed above will give you a cruse rpm of 3200 rpm, which is getting closer.

If it's not going to be a DD, why not 100+ oct unleaded? It's not like you'ld be driving it all the time. Your DCR will probably change a bit, with the intake closing sooner (41* ABDC). Don't forget, you can have the cam ground with the intake CL advanced or retarded as needed also. This will aslo change the rpm band up 200 rpm for every 4* retarded, or down 200 rpm for every 4* advanced. Keep the V-t-P clearance in mind when doing this.

Well, I was using a couple pieces of box tape stretched across the chambers, and a syringe type thing used to squirt medication down childrens' throats (10mL graduated markings, but not incredibly precise). I have a piece of plexi laying around someplace, I just couldn't find it at the time. I'm going to cc the chamber for both the 2.2L and 2200 when I get a chance, along with the stock 2.2L pistons and both sets of aftermarket 2200 pistons. I can't do the whole piston in bore ordeal because my pistons come out of the block

, and I don't have another block for the others.

A milder cam will definately be necessary, unfortunately (I liked the powerband with the radical cam

), as the valvetrain could easily handle the rpm and the added power would have been nice.

It won't be a DD, but it has to be able to go the 17 miles/day in case the DD dies (it seems to happen a lot with me). So, it doesn't have to be comfortable or practical, but it has to be possible (I'd have to go about 10 miles in the opposite direction to get the 100 octane). I also want to be able to drive it to the track, about 15 miles, without spending more than the entrance fee on fuel lol. Also, I'd like to keep the door open for some boost down the road (REALLY want to try and mount a roots blower on something sometime), and stepping up to leaded race gas for that would be rediculous. Although, if they ever decide to open up an ethanol station around here, I wouldn't be opposed to that...

The billet cam is a very good point though, as retarding the ICL to bring down the DCR would now be possible with a smaller grind. I can also try the SBC cam dowel idea from the GM build guide to pull it back (not sure what all that entails doing as far a machining, I'll have to re-read).

And trust me, valve clearance has been on the top of my mind since I got those pistons, but they have a lot of meat on top if I need reliefs cut.

fortune cookie say:

better a delay than a disaster.