I remember reading a thread about a JBOer CCing their head(or the little bowls in the valve, its been a while) and they found that the aftermarket valves they bought CC'd less than the stockers theoretically increasing their CR.

Im wondering if the theory could be a viable way to raise the CR of an engine and would the rise be beneficial?

I believe that it was a LD9 head that was CC'd and im thinking of applying it on a L6, but the theory should be the same.

Thoughts?

Tinkles

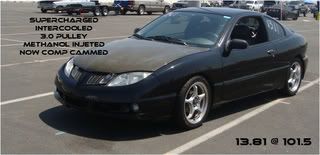

2003 Cavalier 1SV

Bagged and Blown

Are you talking about when the valves are fully seated? Or the actual volume of the valves themselves?

If when they are fully seated, the valves stick into the more than stock (say they are dished out instead of flat) then yes I suppose that would decrease the volume of the cylinder head, but I would start to sorry about possible interference issues (ie - the piston smacking into the valves)

Really it would just be easier to swap out the pistons with higher compression ones.

eskieadam wrote:Are you talking about when the valves are fully seated? Or the actual volume of the valves themselves?

Both. Basically any possible differences that could be in the aftermarket valves that would bump up the CR.

Yes higher compression pistons would be a more efficient way, but what if someone want to raise the CR even more?

Tinkles

2003 Cavalier 1SV

Bagged and Blown

IIRC the GM performance valves aren't dished and "gameoverracing" said the head CC'ed lower. Giving a bump in static compression.

the sivalves.com ss valves for the ld9 have less of a 'dish' in the middle for sure.

i guarantee they raise compression.

Every time I scream "Release", I mean it, you know it. I feel the day. Black 7.

Agreed, the smaller the combustion chamber the higher the CR, less dish in the face will definitely raise the compression.

by doing this it will raise ur compression but by how much? maybe 1/10 to 2/10 of a point of (just a guess).......... if ur building a high comp all motor engine and ur putting o/s aftermarket stainless valves in for the higher airlfow capabilities and strength.......... but as a little added bonus ur also gonna get another 2/10 of a point of compression then ok. but i wouldnt look at them soley as a way to increase the compression u know. ur gonna have to take the head off to put them in why not spend less money and have the head milled? or are they unable to be milled on these engines?

mike

i make neons go fast.........

Uh, excuse me... But, doesn't going with domed valves increase the likelihood of float at higher RPM's vs. dished? And thus require an even higher rate spring to overcome it, which will increase the level of lifter wear (This theory includes side-loading) and possibly cam wear (In flat-tappet apps)?

Go beyond the "bolt-on".

^^ It likely would as a domed valve would have more volume and thus more mass

Nickelin Dimer wrote:Uh, excuse me... But, doesn't going with domed valves increase the likelihood of float at higher RPM's vs. dished? And thus require an even higher rate spring to overcome it, which will increase the level of lifter wear (This theory includes side-loading) and possibly cam wear (In flat-tappet apps)?

Its not that they're domed, its that they're less dished. I'm not sure what reasoning would be behind it on the part of the valve manufacturer other than decreased machining time (time=money). And less dish doesn't necessarily mean more mass than a stock valve as it all depends what metal the valve is made out of also. Of course, since most serious builds go with oversized valves anyway, they all increase mass. Thats why you install stronger valve springs and many go with lighter retainers and keepers.

Anyway, back to the topic at hand. Clearly, if the valve takes up more space in the combustion chamber, it will reduce the volume the chamber holds and yes, increase static compression. However, we're talking miniscule amounts and probably nothing that you'd notice on a dyno reading. Although I'm sure there will be plenty of "butt dynos", particularly here, that would probably swear differently.

Arrival Blue 04 LS Sport

Eco

Turbo

Megasquirt

'Nuff said

JerseyJayLN2 (Scarab) wrote:Nickelin Dimer wrote:Uh, excuse me... But, doesn't going with domed valves increase the likelihood of float at higher RPM's vs. dished? And thus require an even higher rate spring to overcome it, which will increase the level of lifter wear (This theory includes side-loading) and possibly cam wear (In flat-tappet apps)?

Its not that they're domed, its that they're less dished. I'm not sure what reasoning would be behind it on the part of the valve manufacturer other than decreased machining time (time=money). And less dish doesn't necessarily mean more mass than a stock valve as it all depends what metal the valve is made out of also. Of course, since most serious builds go with oversized valves anyway, they all increase mass. Thats why you install stronger valve springs and many go with lighter retainers and keepers.

Anyway, back to the topic at hand. Clearly, if the valve takes up more space in the combustion chamber, it will reduce the volume the chamber holds and yes, increase static compression. However, we're talking miniscule amounts and probably nothing that you'd notice on a dyno reading. Although I'm sure there will be plenty of "butt dynos", particularly here, that would probably swear differently.

It's like shaving weight: Every ounce counts in a serious build.

Go beyond the "bolt-on".

jerseyjay- do a set of those valves in a 96-98 ld9 head thats been decked .010 and you wouldnt need to buy high compression pistons because it would go up quite a bit.

Every time I scream "Release", I mean it, you know it. I feel the day. Black 7.