Will use a LD9 for the basis of discussion.....

Stock LD9, VIN T motor

Engine Type Inline 4 Cylinder

Displacement 2.4 Liter (146 CID)

Bore: 90 mm 3.54 in

Stroke: 94 mm 3.70 in

Firing Order: 1-3-4-2

Horse Power: 150 @ 5600 rpm

Torque Rating: 155 @ 4400 rpm

Oil Pressure @ 3000 RPM 207 kPa 30 psi min.

Oil Pressure @ 900 RPM 69 kPa 10 psi min.

Fuel Delivery: Sequential fuel injection (SFI)

Thermostat opening temperature 180 degrees F

Rod and Piston Design

If you wanted a high revving high horsepower motor....

You would want a larger bore piston with a shorter stroke. The engine design would be made over square (cylinder bore is greater than stroke) to make it rev higher.

If you wanted a low revving high torque motor.....

You would want a smaller bore piston, with a long stroke. The engine design would be made under square (cylinder stroke is greater than the bore) to make it generate higher torque.

Our LD9 engines in stock form are designed to be more of a torque loving motor.

I have been thinking of this since Brad brought up longer rods. "

Click Me"

ammfab wrote:i just googled stock stroke and rod length for the ld9. i found the rod length to be 5.710 (145.0mm) and the stroke to be 3.700 (94mm). then to find the rod stroke ratio (r/s ratio) u devide the rod length byt the stroke and get 1.54.

when u increase the rod length by lets say .300" to get a new rod length of 6.010 and then when u do th emath again u get a new r/s ratio of 1.62 which is better. it decreases side loading on the cylinder walls like the guys mentioned above which will free up some hp at the same time ur kepping the piston at TDC (dwell) for slightly longer also under the cylinder pressure from the combustion to give it a little more thrust on the way down............ u know what i mean.

as for the new pistons......... yeah u will need new ones with the pin bores moved further up on the piston. they should be moved the same amount as the rod length increase so that it lowers the pistons back down to the original postions, to prevent them from running into the head.

in the event that u have enough room between the head and pistons after u put long rods in and u opt not to run new pistons (because u have enough room), i dont think it will effect the compression ratio at all becaue ur engine is still drawing in the same amount of air as before and the piston dome hasnt changed any. compression ration is changed by the piston dome not putting a longer rod or bigger stroke in.

mike

DaFlyinSkwirl (PJ) - APU wrote:want to know what the skwirl has been up to? I've been doing a lot of homework for this coming year, deciding where I should take the skwirl next. A lot of you will be pleased to know that I plan on staying in the all motor category and mixing it up with ben for another year, and possibly section 8 cav with the 2.6 liter twin cam.

I am doing bottom end modifications this year, but a lot of people may be wondering whats going on... I've been doing TONS of homework the past 6 months, and have finally come to a decision. A lot of people may think I'm trying to accomplish a 2.4 ecotec swap.. and rational thought would agree.. no replacement for displacement right? well I'm going a route that some may think is a bit crazy... but take a look at this article and it may give you a slight idea as to my thought process:

ignore that this is from honda magazine.. those who are savvy know that if you're looking to copy/learn anything for all motor 4 bangers... honda is the company and aftermarket to look at for tips/tricks.

Rod/Stroke Ratio - What's Your Angle?

Dip into the intricate world of internal engine geometry and look closely at something you know very little about: rod/stroke ratios. (C'mon, admit it!) Editor Bob demystifies.

writer: Bob Hernandez

If there's one truth about Honda engines, it's that they like to scream. And Honda enthusiasts like to make them scream. The numbers on the tach reach so high, Honda practically offers the license: Go ahead. Make it sing. It's good at it. So long as you don't miss a shift, all is bliss.

Lightweight components, stronger materials and shorter strokes enable modern four-cylinder engines to spin very fast, yet last longer than ever. A tremendous amount of science goes into engineering and creating these high-spinning machines, most of it rooted in elementary principles of physics and geometry-fundamentals anyone planning to build an engine should know.

Understanding rod/stroke ratio, or the amount that a rod deviates from an imaginary straight line extending from the center of the crank journal to the center of the piston, is key to knowing how these machines deliver power at high rpm.

Determining the Rod/Stroke Ratio

To determine a motor's rod/stroke ratio, divide rod length (distance in millimeters from the center of the big and small ends) by stroke. A B18C1, for example, combines 138mm rods with an 87.2mm stroke for a 1.58:1 ratio.

Most engine builders shoot for a ratio between 1.5:1 and 1.8:1 on a street motor, with 1.75:1 considered ideal, regardless of application. (The most highly developed four-stroke engines in the world-F1 and motorcycle engines-have rod ratios of more than 2:1.)

The rod/stroke ratio affects several engine dynamics, including piston speed and acceleration, piston dwell at top dead center and bottom dead center, piston side loads, cylinder loading and bearing loads. Many of these elements play roles in engine aspiration, combustion and wear.

Generally, a lower ratio means a high rod angle, creating greater potential for accelerated wear to cylinder walls, pistons and rings. A low enough ratio, due to the severity of its rod angle, can drive a piston right into the cylinder wall.

Higher ratio engines, on the other hand, don't have the same friction concerns, but compromise in other areas. Air does not fill the intake ports with the same velocity, and there is less demand for the ports to flow as well since there is more time to fill and scavenge the cylinder (we discuss this phenomenon later). This typically means stagnant airflow at low revs and weaker torque. Hey, you can't have it all.

Lower Ratios-A Honda Characteristic

As the chart on this page indicates, many Honda ratios-designed for economy-fall on the low side. Honda produces compact, short four-cylinder engine blocks that don't require long rods. Most Honda blocks also feature a small bore. When coupled with a short stroke, the rod angle is still harsh, though not as bad as if the piston were larger in diameter.

Some tuners take the geometry into their own hands with longer rods. A longer rod makes more torque with the same piston force, and since it's less angular than a shorter rod, reduces sidewall loading and decreases friction. All of this adds up to more power.

Longer rods also give the pistons more "dwell," the brief periods of time the piston is at top dead center and bottom dead center. A longer dwell allows for better flow of intake and exhaust gases since the piston moves slower between up- and downstrokes.

Longer dwell also offers more time to fill the cylinders during the intake stroke and more time to scavenge during overlap. And since the piston hangs out at or near TDC longer, the combustion stroke has more time to deliver a thorough release of energy on to the piston.

In a stroked motor, the piston ultimately reaches greater speeds to cover the additional stroke. The speed makes intake, compression and exhaust strokes more turbulent and, consequently, more powerful. It also comes with its price in component wear, something to consider when looking into parts that increase stroke.

With a short stroke and a long rod, however, the piston accelerates more gently from TDC. It picks up its greatest speed further down the bore, at the point where the crank pin relative to the rod angle reaches 90 degrees. Since the pistons move from TDC slower, the entire bottom end absorbs less mechanical stress.

Advancing Toward A Thin Line

Even the short-stroke/long-rod combo has its limits. To accommodate extra rod length, some builders will move the piston pin higher into the slug, or opt for a deck plate. Either method requires an experienced wrench with access to a lot of custom parts.

Longer rods in a stroked motor can act to offset any increase in rod angle, but also requires a shorter piston. The deeper you dig into a piston to shorten it, the greater your odds of cutting into the oil ring groove and wreaking havoc with oil consumption. Most piston companies in the sport compact market engineer pistons with tighter ring packs and bridge rings to help avoid this problem.

Regardless of whether you take the stroker route or just run longer rods, you reach a point where you can no longer shorten a piston any further without compromising dependability.

Friendly Advice

Most engine builders believe longer rods are better, but a fringe of enthusiasts still dig the low-rpm torque that shorter rods can make. We advise builders who want a ratio of less than 1.6:1 to use the strongest aftermarket rods they can find, given the angle. We also recommend aftermarket sleeves to better fend off the lateral stress created by the rod angle.

Here's one last nugget to impress your friends with: a formula for calculating piston speed in feet or meters per second. The equation illustrates the point that the longer the stroke, the faster the piston travels at the same rpm.

Take a B16A2 vs. an H23. At 7000 rpm, the B16 slug moves 18 m/sec. At the same rpm, the H23 piston hauls additional ass-22 m/sec. Simply multiply stroke by rpm, and voil-minutes of endless doodling in class.

Stock Rod/Stroke Ratio Information For Some Popular Honda Engines

Block Rod length Stroke Rod ratio

D16A6, Z6, Y7, Y8 137mm 90mm 1.52:1

B16A1, A2, A3 134.4mm 77.4mm 1.74:1

B17A1 131.9mm 81.4mm 1.62:1

B18A1, B1, B20B4 137mm 89mm 1.54:1

B18C1, C5 138mm 87.2mm 1.58:1

H22A1 143mm 90.7mm 1.58:1

H23A1, A4 141.5mm 95mm 1.49:1

K20A, A2 139mm 86mm 1.62:1

K24A 152mm 99mm 1.54:1

by comparison:

block stroke rod ratio

L61 94.6mm 141mm 1.5:1

LSJ 86mm 144.84mm 1.68:1

LNF 86mm 144.84mm 1.68:1

LE5 99mm 143.7mm 1.45:1

you'll notice that the LSJ and the LNF have almost ideal r/s ratios.. (their r/s ratio is actually identical to the small block 350)

they're also very close to the K20A, and the K20A2.. which is starting to become a favorite amongst all motor honda enthusiasts, rivaling the B16A1/A2/A3 series in popularity

you can clearly see, since I'm looking for high rpm stability, top end breathing and less mechanical stress.. my bottom end selection is obvious

So my idea is to make an engine that is a torque monster with a stroke to rod ration as close to

1.75:1 as possible.

Pistons in my opinion need to be high compression. 10 or 12:1. Slightly decking the head, and using the 96-98 head or maybe even a 086 head seems like a great choice.

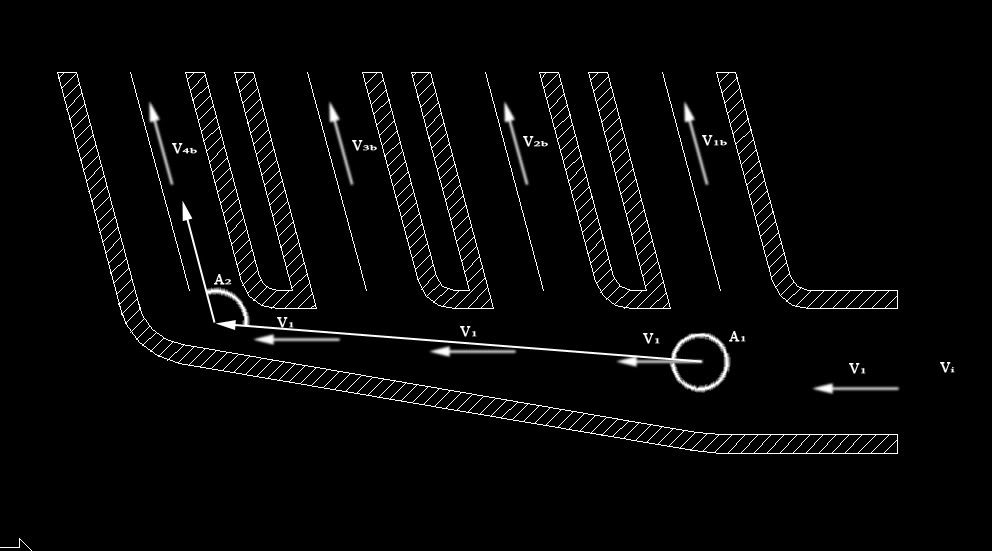

Header design.....

My ideal header in my opinion will be a 4-2-1 header with cylinder 1& 3 and 2 & 4 running together. With short, smaller diameter collectors, long primaries which should give me more power in the low to mid range rpm's, and also keep torque up high.

Exhaust design....

It seems that 2.25 to 2.5" piping from the header back seems to be my best bet. Since i will probably keep my stock rev limiter, and I shouldn't be pushing a lot of air, or revving to hell and back. I WILL be using a nice highflow cat.

Cam Design....

After talking to a few cam people they recommend something around....

240-260 degrees @ .050" with .375" for the intake

260-280 degrees @ .050" with .375" for the exhaust

but for some reason my brain keeps saying something around

215 degrees @ .050” with .360” lift for the intake

215 degrees @ .050” with .360” lift for the exhaust

Any help would be great!

Intake design

Longer thin runners seem to be better for lower to mid range power.

The plenum is where I can not get any kind of consistency. Some calculating say a Larger than stock plenum, and others say smaller than stock.....I'm kinda lost on plenum design. Design wise for low to mid range power stock sized or slightly smaller seems like a good route. but I'm VERY open to opinions.

56mm TB seems to be the sweet spot from my calculations. .....I could be way OFF.

Misc

Personally I do not believe I need a 2.3l oil pump conversion since I plan to not rev any higher than stock. I still might though, since the removal of the balance shafts seem like a great hp gain. Any questions concerns or anything please feel free to ask. The most questions the better.

PRND321 Till I DIE

Old Motor: 160whp & 152ft/lbs, 1/4 Mile 15.4 @88.2

M45 + LD9 + 4T40-E, GO GO GO