But an option for a FMIC would be great if you wish to run small pulleys.

-da chinchilla

Nukkinfuttz wrote:why would think you need constant cooling if it has a built in bypass valve? the purpose of that vavle is to take the SC out of boost, there fore it can generate no heat, becuase its not compressing the air at all. it cant compress it at all becuase thru the bypass, the outlet is connected to the inlet. it will equalize, therefore no boost, no heat.

the underhood temps of 210 degrees are perfectly normal. they a stock car. this is becuase the manifold id directly connected to the engine heat, which its temp is 195-220 dictated by the themostat. all this head being removed from the engine is then radiated out of the coolant, by a fan blowing it directly onto the engine manifold. the engine is making the manifold heat soak, its not the blower doing it. Im sure you may not be aware of this because a factory car has a composit intake that does not heat soak much, but the aluminum sc mani will. the stock quad 4 aluminum intake mani does the same thing.

as soon as you get going this heat will clear the mani. if you still dont like it, use a phenolic spacer. its cheaper than a H/E setup and will do the same thing, since the bypass vavle is making sure the blower does not generate any heat off boost.

You are so far off on everything you just posted I hardly know where to begin.

Just because the sc is not creating boost does not mean it is not generating heat. The sc is being spun therfore there is heat being produced by the friction of a spinning unit. The amount it heats up the air is porpotionate to how fast it is spinning and how much heat is being removed from it. Sure it is bolted to the head so it is going to get hot, but the cooler we can keep it the better. This is why the heat exchanger comes into play. It flows coolant through the manifold to remove heat. I am well aware that compressing air creates heat but it is not the only thing contributing to sc heatsoak.

FYI On a 70 degree day with the cruise set at 70mph on a long interstate trip (out of boost since the cruise was on) I was seeing 170 degree IAT's with the 2.5" pulley on my M45. The same exact conditions with the stock 2.8" pulley I was seeing 120 degree IAT's and with the 2.7 I was seeing 135 degree IAT's. I have done countless hours of monitoring my IAT's with HPT so this I am sure of.

IAT temps off 200+ degrees are not acceptable under any circumstances! You will loose a sinificant amount of power since the computer uses IAT temps as well as some other factors such as input from the knock sensor to determine timing not to mention we all know cool air is better for power due to the density. I deally we should not be seeing temps more than 25 degrees above ambient air temp

I have heard but have not been able to verify that the computer starts pulling timing at anything over 125degrees.

A phenolic spacer would be a great idea but is not going to even come close to providing the same benefit as a H/E

After having beat relentlessly on a all stock 07 Cobalt SS for 5 days I can say that the H/E is absolutly needed. I never experienced heatsoak and it seemed to pull just as hard time after time. My car would have pulled hard the first few runs and then heated up to the point it felt like it was hardly adding power.

Edited 2 time(s). Last edited Friday, October 31, 2008 11:52 AM

FORGET GIRLS GONE WILD WE HAVE GOVERNMENT SPENDING GONE WILD!

justin stinespring wrote:wow this is looking like its actually gonna happen. anyone have an estimate on about how much power its capable of on an ld9? cuz if it can put down some good numbers id jump aboard on this as well. ive been waiting for this to happen since the first person started this setup. so this is really exciting for me

I would say around 300whp. It is really hard to say for sure. How cool you can keep the charge of air will be the make or break factor.

Edited 1 time(s). Last edited Friday, October 31, 2008 11:56 AM

FORGET GIRLS GONE WILD WE HAVE GOVERNMENT SPENDING GONE WILD!

Well, all i can say is i experienced differant conditions. When i first did the M90, it was non-bypassed, and non intercooled. Even on short trips it would get REAL hot. so, i added a bypass valve, and a phenolic spacer, and I could drive 25miles to work, get out, open the hood and put my face of the charger becuase it was cool. Once i did go into boost, my temps would go upto 250F. so, i remote mounted it, and now go through a FMIC. now, the charger stays cool when cruising, and 100-110 degree's after the FMIC when in boost.

We have also shot a stock aluminum manifold on a quad 4 at 180*F , then added a phenolic spacer and shot 120* with a infared therometer. it all makes perfect sence to me.

I still stand by my earlier post. I guess we'll just have to agree to disagree on this point

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

and as far as the "becuase its a rotating mass, it must be making heat thing..."

Magnus SC claims that by using a bypass valve, the M90 will only draw 1/3HP when cruising.

1/3HP turned into heat would not be significant enough to heat soak the SC. its still being cooled by incoming air.

another way of picturing how much 1/3 of a hp is, if you were to have an electrical motor at that rating, it would only draw about .25a @480vac. so, 480 x .25a = 158 watts of power. com'on, how much heat could you contribute to a machine that is constantly getting air cooled by incoming air with 158W? not much.

the M62 would draw even less effeciency loss, as its a smaller unit that the example above. two household lightbulbs use that amount of power. its nothing.

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

i was a little off in my above estimation...

http://www.airlinktransformers.com/faq.asp?q=8

this links shows that to convert HP to Watts , you multiply the horsepower rating by 746

so, .33HP x 746 = 246 watts.

common household lightbulb = 90 watts

246w / 90w = 2.735

so, the heat disappation into the charger would be equal to the amount of heat 2.7 household lightbulbs could radiate. its still nothing.

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

how much cooling effect would your engine provide in airflow during crusing is the next logical question.

2.4L = 140CuIn of displacement.

convert to CuFt

140 / 12 / 12 / 12= .081 CuFt

at cruising speed of lets say 3500 RPM's

.081 x 3500 = 283CFM's.

time VE at that condition. lets guess on the low side, 55%

283 * .55 = 155 CFMs druing crusing would be cooling the charger.

If 155CFM's can negate 246watts of power, then something is wrong.

there is probably a larger heat source involved... like the engine and radiator. There some serious heat coming from those items.

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

Nukkinfuttz wrote:

We have also shot a stock aluminum manifold on a quad 4 at 180*F , then added a phenolic spacer and shot 120* with a infared therometer. it all makes perfect sence to me.

I just want you to know we are in agreement on the phenolic spacer being a good idea.

I don't know if this is an option.

I sent Vulcan a PM saying

"Nukinfutz brought up a really good point when he mentioned a phenolic adapter. I was thinking since you guys already are having 2.4 flanges made why not make one out of phenolic material to go in between the head and manifold. This would greatly help reduce the heat transfer from the head to manifold"

Vulcans response

"This would help, however, all our flanges laser cut at a local place which cant cut garolite (phenolic material). Either way the supercharger itself also makes heat generated from friction inside. Im going to think it out, i probably wont be on the org much this weekend as im going to chicago for my cousins wedding this weekend. Ill try and brainstorm while im out and about, things like this bother me until i figure out a solution so no worries. Ill keep you updated. All the aluminum flanges should be getting cut this monday so i can start on the manifold if i have a design figured out."

So at this point I am going to try and get ahold of Chris Fontana and see about him having somestraight 2.4 phenolic spacers made. I know this would be helpful to anyone with a metal 2.4 manifold such as the Venom OBX or any custom metal manifold.

FORGET GIRLS GONE WILD WE HAVE GOVERNMENT SPENDING GONE WILD!

Phenolic adapter with o-rings built in would be nice, I had them on my old 3400 and made the gasket thing much easier. The spacer is a good idea as long as there is enough space for the plenum and the front of the car. I guess have vulcan save about 1/2" of extra clearance when making it.

Wade I honestly think iat's wont realy be a problem for a while unitl you start dropping pulley sizes and with winter coming. But the option for a fmic/he is a great idea. I kinda wish Id stayed sc'd through winter and went with the 2.5" pulley just to see how it feels, but I do love the turbo

Wade Jarvis wrote:This is kind of my fault here. I know I had said I did not care if it had some type of intercooler or H/E since I was planning on using alky injection. Looking back on that I see the error of my thinking as I had the wide open throttle temps covered but had not fully realized how important having the H/E is for constant cooling. We must address the heat issue as it is the biggest problem with a roots type setup.

.

this comment lead me to believe the only reason that a H/E was desired was for offboost cruising. I was trying to prove that it is not needed in this condition, a phenolic spacer would take care of it.

I agree, you guys would be most pleased if it did have a H/E, but dont let cruising be the only reason for the added cost, becuase its not nessesary to control heat with such an expensive system duing cruising. if you would be happy with water injection as your intercooling method during boost, then a phenolic spacer is all thats needed offboost.

i would still highly recommend a H/E though!

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

Wade Jarvis wrote:This is kind of my fault here. I know I had said I did not care if it had some type of intercooler or H/E since I was planning on using alky injection. Looking back on that I see the error of my thinking as I had the wide open throttle temps covered but had not fully realized how important having the H/E is for constant cooling. We must address the heat issue as it is the biggest problem with a roots type setup.

.

this comment lead me to believe the only reason that a H/E was desired was for offboost cruising. I was trying to prove that it is not needed in this condition, a phenolic spacer would take care of it.

I agree, you guys would be most pleased if it did have a H/E, but dont let cruising be the only reason for the added cost, becuase its not nessesary to control heat with such an expensive system duing cruising. if you would be happy with water injection as your intercooling method during boost, then a phenolic spacer is all thats needed offboost.

i would still highly recommend a H/E though!

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

yeah im an definatley very interested in getting in on this. i get paid in approx 12 hours, so if vulcan needs another buyer to fund the project i could probably pinch some pennies to help make this happen.

and a big thanx go out to wade and nukkinfutz for all the great info. im sure i speak for everyone else thats interested in this as well.

I know I would like to have some sort of cooling of the SC ( whether it be IC or HE ). I think the conversation we are having is good, but I am waiting to see what Vulcan says once they get the car apart.

Jason

99 Z24 Supercharged

157hp/171tq - NA

190hp/170tq @ 6psi

LD9 for Life

Wade Jarvis wrote:Nukkinfuttz wrote:

We have also shot a stock aluminum manifold on a quad 4 at 180*F , then added a phenolic spacer and shot 120* with a infared therometer. it all makes perfect sence to me.

I just want you to know we are in agreement on the phenolic spacer being a good idea.

I don't know if this is an option.

I sent Vulcan a PM saying

"Nukinfutz brought up a really good point when he mentioned a phenolic adapter. I was thinking since you guys already are having 2.4 flanges made why not make one out of phenolic material to go in between the head and manifold. This would greatly help reduce the heat transfer from the head to manifold"

Vulcans response

"This would help, however, all our flanges laser cut at a local place which cant cut garolite (phenolic material). Either way the supercharger itself also makes heat generated from friction inside. Im going to think it out, i probably wont be on the org much this weekend as im going to chicago for my cousins wedding this weekend. Ill try and brainstorm while im out and about, things like this bother me until i figure out a solution so no worries. Ill keep you updated. All the aluminum flanges should be getting cut this monday so i can start on the manifold if i have a design figured out."

So at this point I am going to try and get ahold of Chris Fontana and see about him having somestraight 2.4 phenolic spacers made. I know this would be helpful to anyone with a metal 2.4 manifold such as the Venom OBX or any custom metal manifold.

Just wait until you guys see what i got my hands on it.

justin stinespring wrote:yeah im an definatley very interested in getting in on this. i get paid in approx 12 hours, so if vulcan needs another buyer to fund the project i could probably pinch some pennies to help make this happen.

and a big thanx go out to wade and nukkinfutz for all the great info. im sure i speak for everyone else thats interested in this as well.

Every penny does help... Im going all out on this project and i think everyone is going to extremely pleased to see the lengths im going through to make sure everything works out perfect for you guys.

Estimated 4.00 BTU/hr F of thermal transfer.

fantastic! looks great. Who does the CNC programming? did you just take them a gasket and tell them to do it? or did you have to submit a CAD file? Laser or waterjet? How long did it take to get those in your hands after you said "go"?

I had some spacers made for the quad 4 last year, and it took almost 3 months for the order to be machined, so im very impressed that you have these in your hands only two days after it was even mentioned. Thats a good show of faith that finally this M62-LD9 mani will be complete, and not just talk like the rest. Bravo!

M90'd Built LGO-15 PSI

http://webstarts.com/quadper4mance

Your missing the PCV passage in the spacer. it goes between #2 and #3 runners just about where that notch is.

mitdr774 wrote:Your missing the PCV passage in the spacer. it goes between #2 and #3 runners just about where that notch is.

I was thinking the same thing, but they look great other wise

Jason

99 Z24 Supercharged

157hp/171tq - NA

190hp/170tq @ 6psi

LD9 for Life

Ill have to drill the PCV on our drill press with cnc assistance.

I programmed it myself in AutoCAD and its the same pattern that is used for the supercharger intake manifold flange, and i have a friend who works at a machine shop, he is not the most reliable source for parts, sometimes he can get things right away but most of the time not. I ordered in the material myself and only ordered enough for 2, i had seen talk of something along these lines before so i wanted to get a head start, i didnt think he would be able to provide them so quickly so i didnt want to promise anyone these parts or that i could have them made. I sent him the file for them early this week (i think it was tuesday), he called me last night and said he actually had cut them, apperently they cut very quickly compared to metal so it was no biggy to squeeze them in. Does anyone have a picture of exactly where the PCV port is located exactly?

I like to keep things moving along quickly as thats the only way to do business.

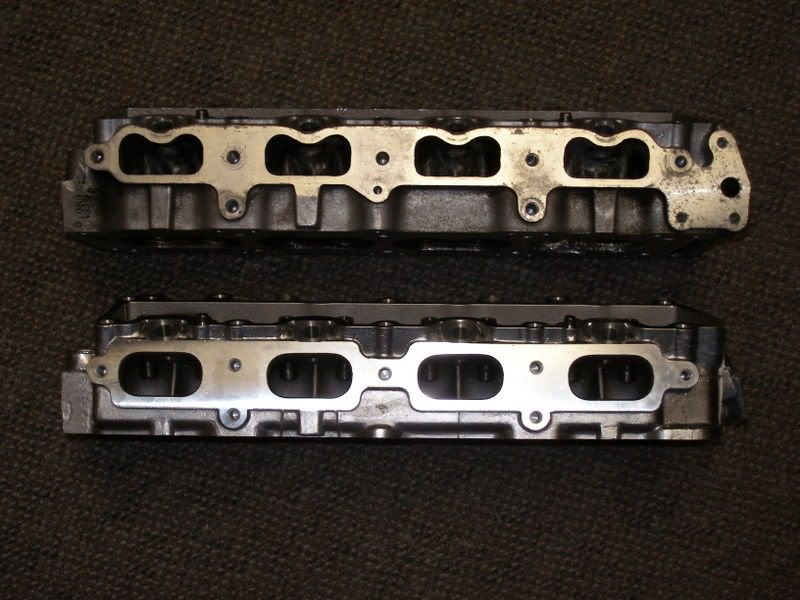

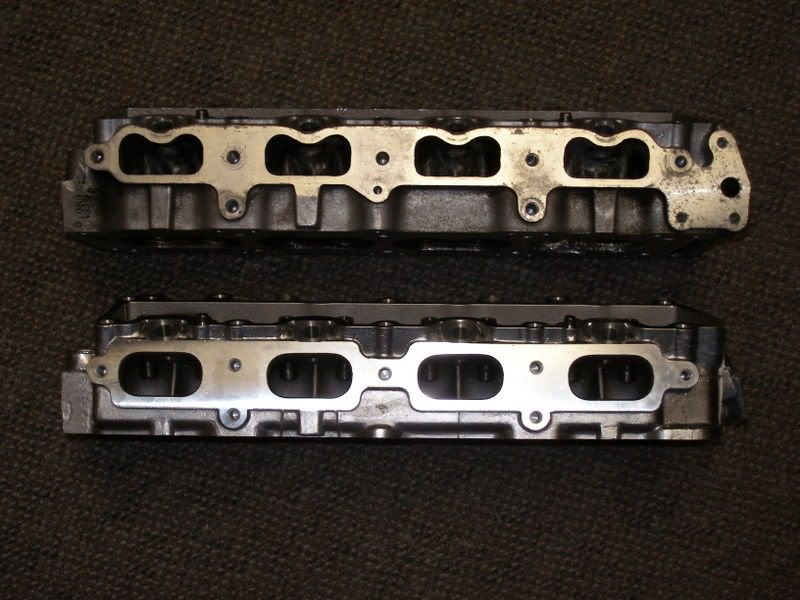

Top head is a 2.4L head. The passage is between #2 and #3 runners right below the manifold bolt hole.

Hmm, my design just misses it. Is it threaded or anything? It might be better for you guys to drill it slightly larger to a size R drill bit, then tapping it to a 1/8NPT and threading a fitting in! Not to mention that is a very small PCV vent for a boosted engine.

Also, was that 2.4L head ported?